Aerospace

Our copper and aluminum MicroGrid® materials protect composite aircraft surfaces and rotor blades from lightning strikes.

Our Certifications and Organizations

|  |  |

How Dexmet Lightning Strike Materials Protect Carbon Fiber Aircraft Surfaces

Aluminum has been the principal material used in aircraft and aerospace construction for the past 70 years. With the growing interest to construct more efficient aircraft, manufacturers are designing more components out of light-weight composite materials.

The new generation of aircraft utilizes carbon fiber for major structures including the fuselage, wing, engine nacelles, flaps, wing tips, and even rotary blades and fuselage on helicopters. Composites, however, are poor conductors of electrical current. Without proper protection, they are susceptible to severe damage in the event of a lightning strike.

When Dexmet expanded aluminum and copper MicroGrid® materials are incorporated into the surface of these composite structures, the lightning strike energy is dissipated over the surface of the component, which prevents damage to the composite material below.

MicroGrid® precision expanded metal foils from Dexmet are the materials of choice for lightning strike protection in composite aircraft structures. We've been developing the technology for the last 30 years with all major aircraft OEMs and we have the most configurations available in the industry.

Dexmet is the preferred supplier on many of the new generation designs for Airbus, Boeing, Bombardier, Embraer, and the majority of aircraft and rotorcraft manufacturers around the world. Aircraft manufacturers realize the benefits of using Dexmet’s advanced expanded materials over the outdated technology of woven wire and come to Dexmet for technical knowledge when designing new components.

Common MicroGrid Lightning Strike Materials

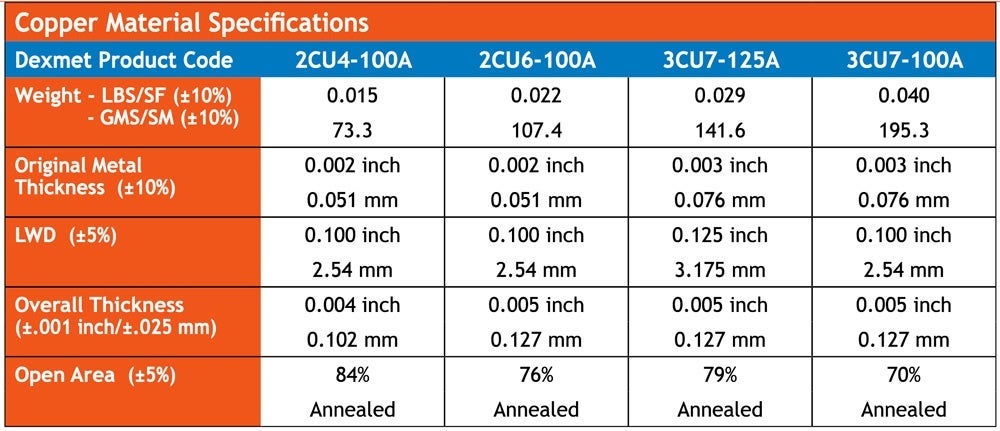

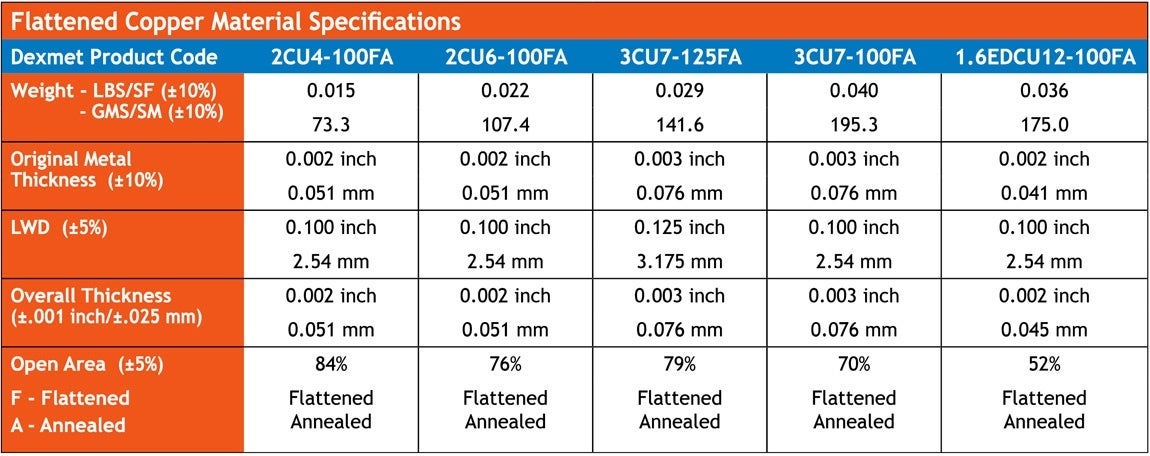

The charts below provide information on typical L/S materials

Aluminum Specifications

Copper Specifications

Flattened Copper Specifications

Engineered Materials for Aerospace & Defense

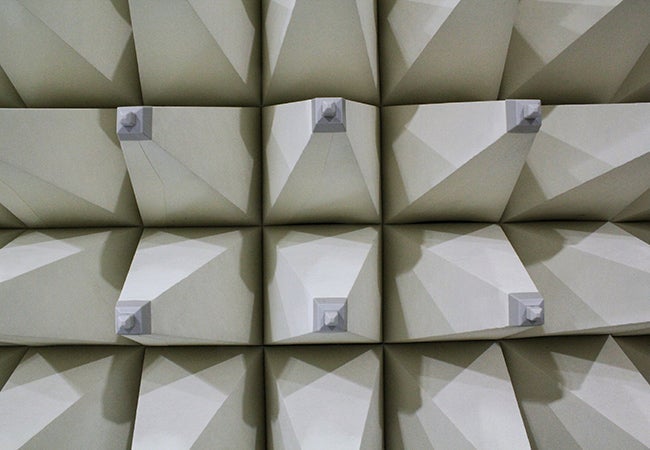

MicroGrid’s single unit structure is superior to woven material in that it won’t unravel or have loose strands that become problematic during processing into a pre-preg material or when conducting a dry lay-up.

The homogeneous design also ensures uncompromised conductivity between strands when forming the material to a variety of shapes and contours and provides a smooth surface on the end product. MicroGrid’s biggest advantage is Dexmet’s ability to tightly control the manufacturing process to meet a specific weight, open area, and conductivity requirement.

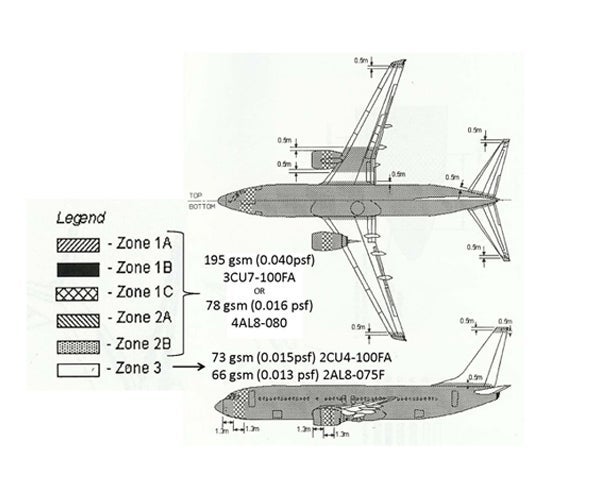

This allows engineers the option of varying materials according to specific strike zones on the aircraft, minimizing the overall weight. Our common materials have the ability to withstand a Zone 1A strike of 200,000 amps.