Automotive

The versatility of Dexmet precision expanded metals & expanded plastics make it a perfect choice for industrial and automotive products.

Our Certifications and Organizations

|  |  |  |

Market Overview

The Industrial & Automotive Market Segment comprises of a number of industrial applications utilizing Dexmet's expanding technology.

Within filtration systems, Dexmet's expanding technology can produce pore sizes to achieve particle filtration, specific flow rates and pressure drops to specifications. Primarily used as a pre-filter or a filter support material in pleated filters, flow rates typically are minimally affected compared to woven mesh when using Dexmet's proprietary DDB PolyGrid®. Dexmet specializes in expanding products from high temperature fluoropolymers (PTFE, PFA, FEP), offering materials free of harmful chemical Perfluorooctanoic Acid ("PFOA" or "C8") which is found in competing extruded and woven mesh. Dexmet's ultra-thin material process capability also allows filter manufacturers to increase the pleat density 25%, enabling filter designers a competitive advantage traditionally manufactured filters. The Company also produces a wide range of stainless steel products for primary filtration for several customers in various fluid and gas filtration markets.

Primary automotive markets include oil-less bushings, high temperature gaskets, heat shields, catalytic converters, fuel filters, inlet screens and speaker grills. Low friction, oil-less bushings are continually being placed in every moving part replacing the need for grease and lubrication points. As new platforms of vehicles are introduced, more of these greaseless bushings are being introduced. Some of the newer platforms vehicles have quantities exceeding 200. The primary material is phosphor bronze, which by chemistry is a lubricating metal, but stainless steel and aluminum are also commonly used in harsh environments or light duty respectively. High performance gaskets are also utilize expanded stainless and low-carbon steel to increase the structural support of high temperature gaskets used for head and exhaust gaskets.

Dexmet's expanded foil materials offer both EMI and RFI frequency shielding protection as well. Common applications are flat ribbon cable used in computer electronics and telecom applications, panel gaskets, electronic enclosures and various portable devices. Dexmet offers fine mesh MicroGrid® to these markets typically manufactured from copper, aluminum, nickel and monel™.

Automotive Engineered Materials

With collision avoidance systems gaining prominence in the automotive marketplace Cuming Microwave has designed solutions to work at the most popular millimeter wave frequencies of 24 GHz and 77 GHz. These materials are very effective at eliminating cross talk and RF leakage in small packages required for these applications. Typically these housings require thin loaded elastomers. Our C-RAM FLX product line as well as our cavity resonance absorbers GDSS, RGD-S 117 and 124 are the most popular solutions for these applications. These products can be supplied with pressure sensitive adhesive and diecut or waterjet to your specifications.

Product Applications

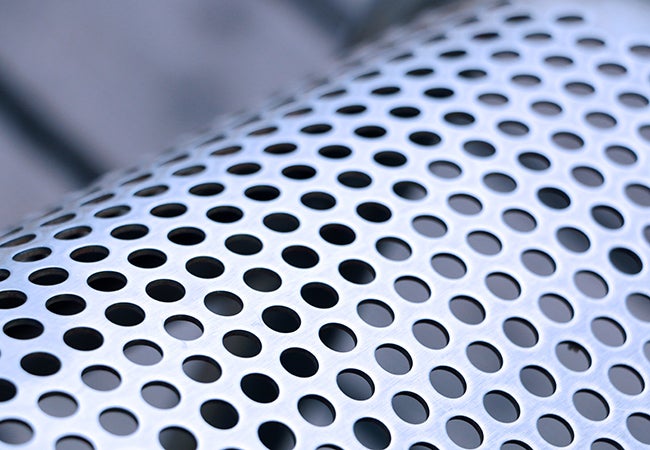

Expanded MicroGrid for Automotive Applications

Dexmet precision expanded metals are used in a host of primary OEM and aftermarket automotive products. Typical applications include: low-cost greaseless bearings, high temperature gaskets, airbags, inlet screen and filtration. Dexmet bronze mesh is used as a lubricating material and support structure in bearings primarily for automotive applications. In addition, these expanded metals are ideal for automotive speaker grills & covers, light covers, protective light mesh and decorative applications. Automotive engineers continue to adapt Dexmet expanded metals and some expanded plastics in innovative ways.

Dexmet expanded metals and foils are the materials of choice in airbag filters. As compared to the typical extruded material or woven material, Dexmet expanded metal saves money by eliminating waste and will not unravel during processing. Dexmet expanded metals and foils are available in a wider range of widths, thicknesses, and open area configurations than any other material type. This combined with the ability to perform custom slitting and edge treatments makes Dexmet the premier supplier for airbag filter materials.

Common Industrial & Automotive Applications

For MicroGrid® Expanded Metal Foils and PolyGrid® Expanded Polymers

Automotive

Dexmet precision expanded metals & expanded plastics are used in a host of primary, secondary and aftermarket automotive products. Typical applications include low-cost bearings, airbags, air filters, and oil filters. Also, expanded metals and plastics are ideal for inlet air screens, speaker grills & covers, protective mesh and decorative applications. Automotive engineers continue to adapt Dexmet MicroGrid® expanded metals and Polygrid® expanded polymers in innovative ways.

Filtration Media

Separation and purification are key criteria for industries that process water, food & beverages, chemicals, and pharmaceuticals. Dexmet custom manufactures all MicroGrid® and PFOA-free PolyGrid® materials in a multitude of open area configurations with controlled pore sizes to provide a more consistent flow rate for your filter application.

Dexmet Corporation introduces PFOA-Free PolyGrid® Expanded Fluoropolymers. PFOA (Perfluorooctanoic Acid), widely used as a polymerization surfactant in making fluoropolymers including PTFE, PFA and FEP, has fallen under scrutiny by the EPA and FDA for its potential toxicity and widespread presence in the environment and human population.

Filter designers now have a solution to remove this harmful additive from their current or new filter designs that utilize PTFE, PFA, and FEP with a PFOA-free expanded material from Dexmet. PFOA-Free expanded PolyGrid® is also excellent for applications in the medical, filtration and separation, food processing and food packaging industry.

EMI/RFI Shielding

The Dexmet MicroGrid® EM series of expanded metal foils (EMFs) are versatile, effective materials for shielding against electromagnetic interference (EMI). They are electrically continuous and, unlike knit or woven meshes, exhibit consistent and predictable conductivity. Thin, strong, flexible and lightweight, open area products, EMFs will not fray or unravel, and conform readily to complex surfaces, making them well-suited to composite manufacturing processes.

Standard configurations include copper, aluminum, nickel and Monel meshes at .002 and .003″ thick (50 and 75µm). Dexmet can readily produce custom types using other metals and foil thicknesses, including Cu and Al types down to .001″ (25µm). The open area of the mesh can be precision-tailored to meet user requirements for weight, resistivity, formability and shielding effectiveness.

Industrial

Dexmet supplies expanded metal foils and polymers for over 100 different industrial applications. From medical equipment to decorative enclosures, expanded materials can be manipulated for almost any application. The versatility of our open-area products makes it easy to dial in specific characteristics when designing a new product.

Automotive Applications

The versatility of expanded products from materials choices to configuration variability make Dexmet materials the perfect choice for applications in the automotive market.

Automotive Greaseless Bushings

Over the past twenty years, automotive manufacturers have made a concerted effort to remove all bearings and bushings that utilize grease for automobiles. This shift has been slow to take effect because producing a bearing or bushing that can withstand extreme loads and continual abuse has been a challenge. The first generation of PTFE based bushings were for low load/low duty applications found on trunk and hood hinges, seat backs and some interior components. The transformation to the higher load applications, such as door hinges and light suspension components, gained momentum when new designs incorporating a woven or sintered phosphor bronze (a naturally lubricating metal) as a support structure for the PTFE became available.

The current generation of bushing is designed for higher duty and heavier suspension components on cars, light trucks, and off-road equipment and utilize an aluminum or steel backing material in addition to an improved expanded phosphor bronze support structure for the PTFE. The performance gains utilizing an expanded product have made it the material of choice with engineers and the majority of the new bushings being designed will utilize an expanded product. Currently, there are some new model cars with over 200 bushings and this number will continue to increase as these low friction, oil-less bushings are utilized in every moving part within the automobile. Additional applications for these bushings include motorcycles, off-road equipment, bicycles, and even appliances.

Utilizing Expanded MicroGrid

Expanded metal can be employed by itself as a plain bearing or bushing. It is generally most effective in this use when loaded with a lubricant, such as grease or babbitt. However, expanded metal is more often used as the structural backbone for plastic plain bearings or bushings. In this approach, plastic (frequently PTFE or similar material) is extruded around an expanded metal core. The expanded metal does not come into contact with external surfaces, but retains the shape of the bearing/bushing and keeps it in place. Dexmet can provide a wide variety of metals, geometries (including control of the z-dimension), and secondary treatments to exacting specifications to meet your needs.

Airbag Containment Screens

Dexmet expanded metals and foils are the materials of choice in airbag filters. As compared to the typical extruded material or woven material, Dexmet expanded metal save money by eliminating waste AND will not unravel. Dexmet expanded metals and foils are available in a wider range of widths, thicknesses, and open area configurations than any other material type. This combined with the ability to perform custom slitting and edge treatments makes Dexmet the premier supplier for airbag filter materials. Please consult with our sales and engineering professionals for specific materials characteristics in regards to your bushing application.

High Temperature Gasket Substrate

Dexmet expanded metals meet the demands of high temperature gaskets for exhaust manifolds. The variability of the expansion process allows designers to dial in a specific strength to the material for their applications. For more rigid exhaust flanges, a smaller opening is used and thicker base materials to provide optimum strength. For manifold gaskets, lighter weight materials with more open area are used. These gaskets use a flattened product to minimize the overall thickness. Materials typically used are low carbon steel and stainless steel. Dexmet expanded metals and foils are available in a wider range of widths, thicknesses, and open area configurations than any other material type.

Air Inlet Screens

Dexmet expanded MicroGrid meshes are perfect for air inlet screens on commercial automobiles and high performance race cars. Typical areas where meshes are utilized are radiator screens, brake cooling inlets and engine air intakes. The openings can be more restrictive to filter out debris and small particles or enlarged for increased airflow. The expanded material also becomes a decorative component to the automobile as well so expanded materials are not only functional but good looking as well.