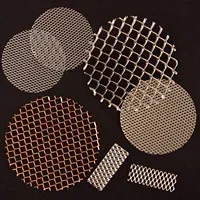

Expanded Metals

Our expanded metal solutions are widely used in the aerospace, electrochemical, medical, and automotive industries that require precision open-area metals to improve their end products.

Our Certifications and Organizations

|  |  |

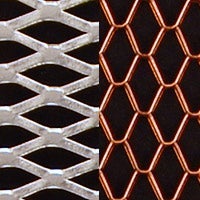

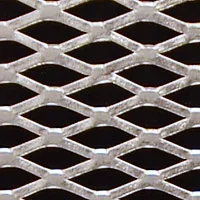

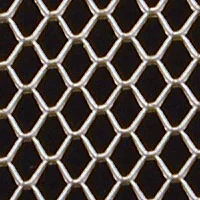

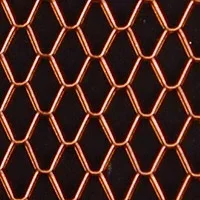

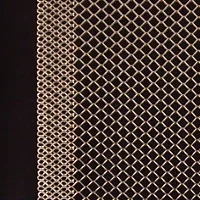

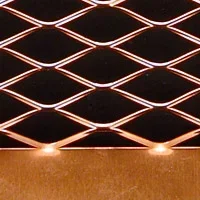

About MicroGrid®

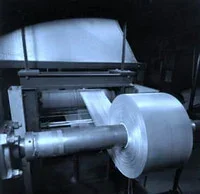

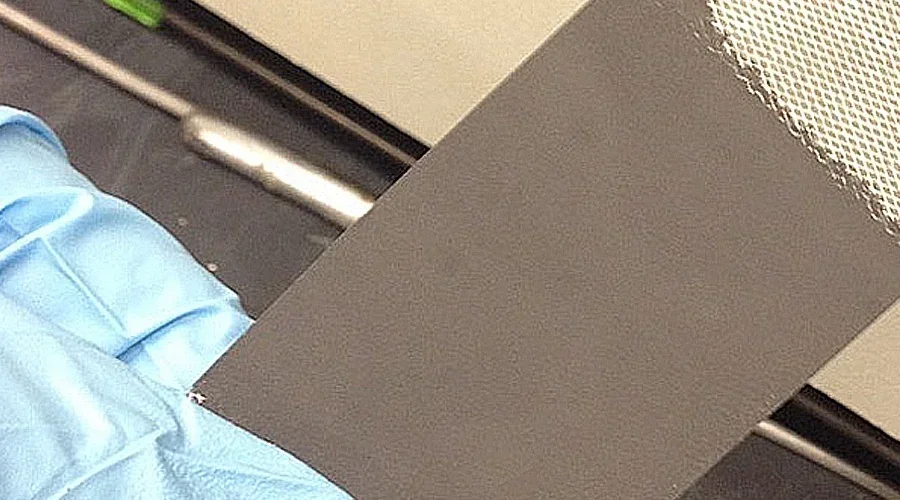

A superior alternative to woven wire, our precision expanded metals are used in a wide variety of applications that require an open-area product. Dexmet expanded metal foils are used for aerospace and wind turbine lightning strike protection, EMI shielding, advanced primary and secondary battery electrode design, automobile bearings and bushings, as well as air and hydraulic filtration systems. All our expanded metals can be tailored to meet specific mechanical and electrical performance parameters. Whether it's EMI shielding effectiveness or lightning strike conductivity, the process of metal foil expansion is infinitely variable and can be fine-tuned to meet your performance specifications. Dexmet MicroGrid® expanded metal foils are available in most ductile metals, or we can work with your proprietary material.

Metals we regularly produce include:

aluminum, copper, nickel, cold rolled steel, stainless steel (302, 316, 409, 430), titanium, brass, zinc, Monel™

- One-piece, single-unit structure

- Eliminates unraveling and contact resistance of woven mesh

- Superior shielding, electrical and heat transfer properties

- Wide range of sizes, patterns, angles and materials

- Specialized process variations, such as flattening, pulling, and annealing available

Dexmet's typical standard expanded metal range can have diamond mesh sizes from .031" to .500″ (LWD). Open Area can range from as low as 30% to as high as 95%. The wide range in open areas can facilitate the use in laminations or coatings with a variety of other materials which may require a material to expand, contract or flex. Applications with unique parameters and requirements are perfect for expanded materials. Dexmet’s extensive manufacturing resources can accommodate many process variations for metal materials in a range of finished thicknesses.

Tool Codes and Configuration Ranges

Dexmet precision expanded metals offer superior performance and material savings for a range of materials and applications.