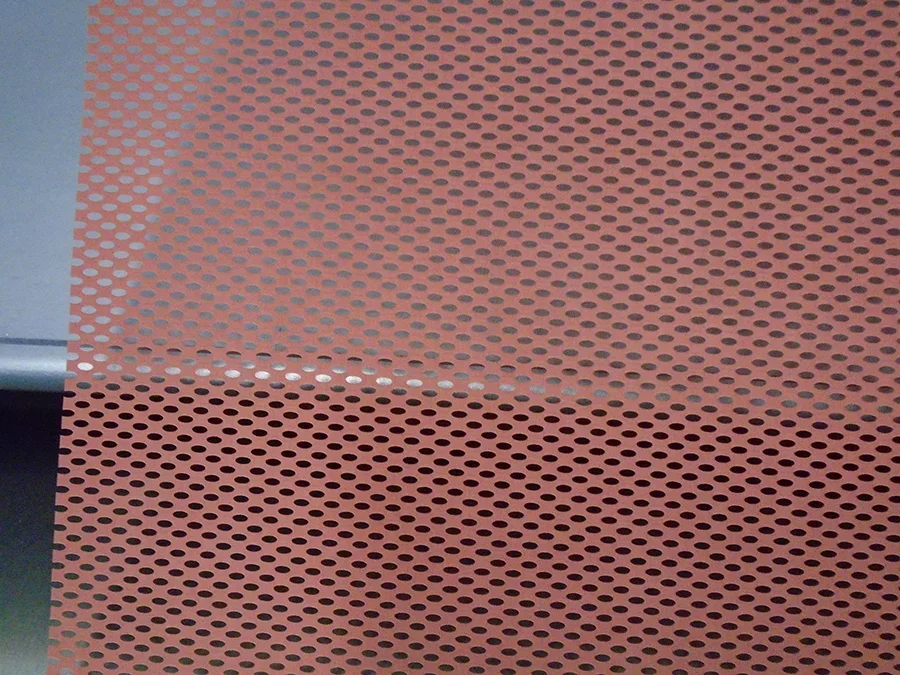

Perforated

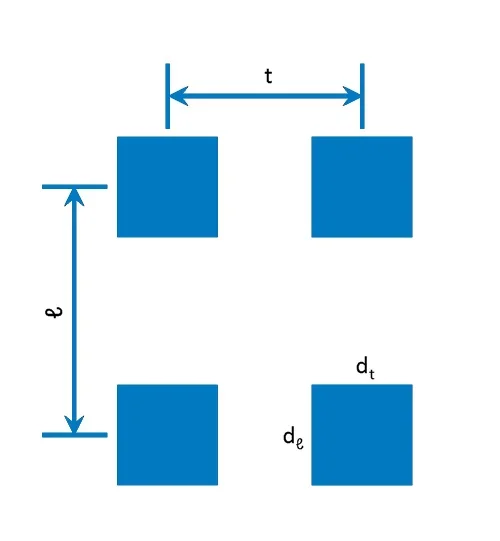

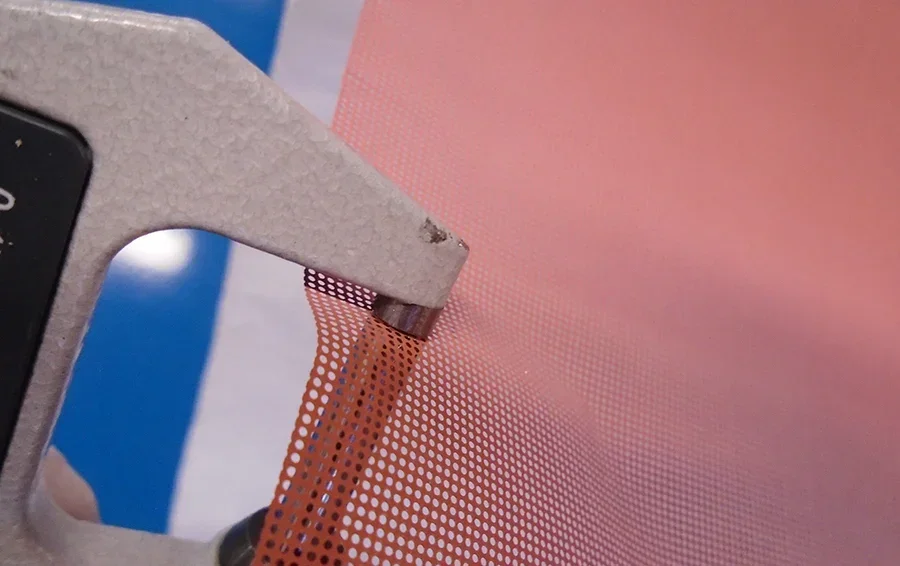

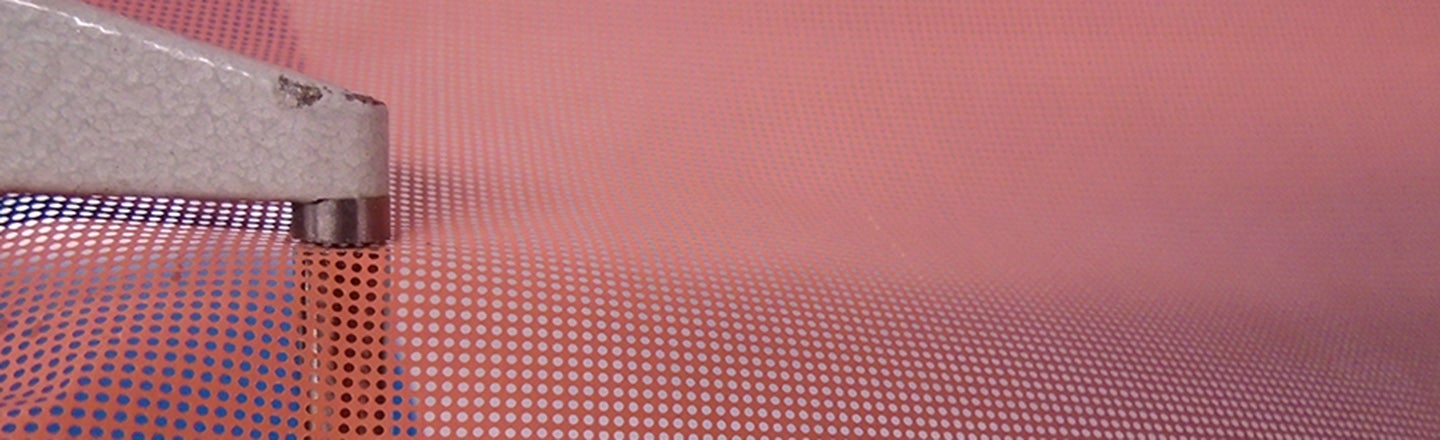

Building on its leadership in precision, thin-gauge expanded foils, Dexmet introduces a complementing line of meticulously-engineered, thin-gauge perforated metals and plastics.

Our Certifications and Organizations

|  |  |

Perforated technology to complement Dexmet's expanded material

Expanded foils have been Dexmet's calling card for over 70 years. No other manufacturer can match the consistency and uniformity of Dexmet's open-area products.

But there are applications where expanded foils meet their limits... The relentless push toward thinner, lighter products has led the company to expand its expertise into an adjacent, complementary technology: Perforated foils.

The precision, consistency, and volume production capabilities of Dexmet expanded products are now available in perforated format. Users in the aerospace, power storage, and filtration industries now have a further range of open-area foils to choose from. Delivered right, and delivered on time.