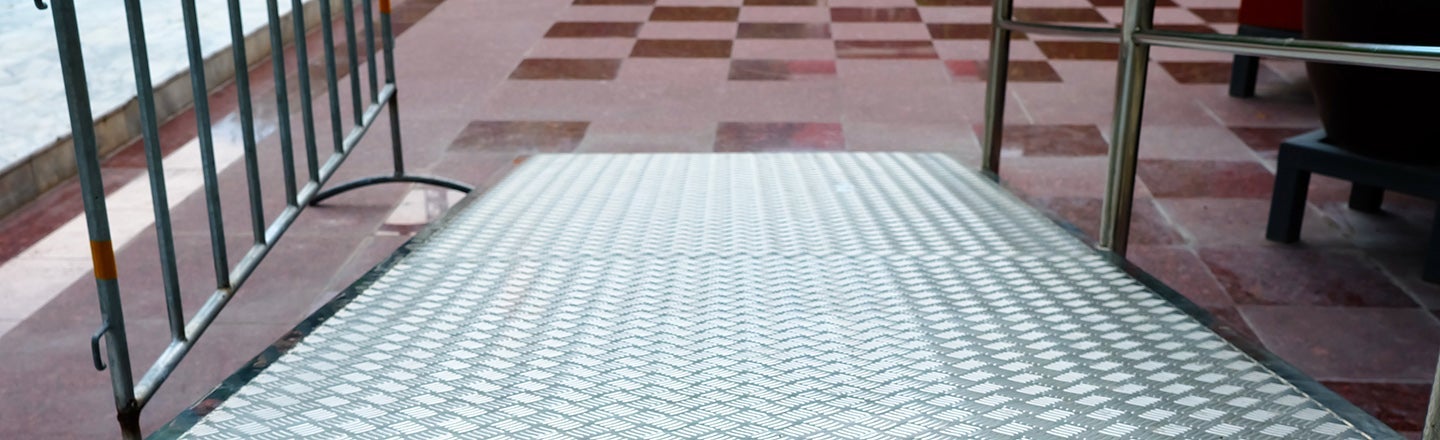

At Cuming-Lehman Chambers we understand the complexities involved when selecting the correct ramp for your anechoic chamber. Every ramp we sell is custom made; designed to be user friendly; beefy enough to handle the job and durable enough to last a long time.

Ramps

Knife-edge door sills are very sensitive; it’s recommended that the sill not be used as a step for pedestrian traffic, therefore when bringing in heavier test articles with a cart, bag-wagon or forklift the correct ramp must be utilized.

|  |

Some important points to consider when purchasing a ramp include:

- Capacity or Rated Load – The weight of the greatest moving load (including goods, persons and transport equipment) for which the product is designed must be accounted for. Be aware whether quoted capacities are Total Load (Uniformly Distributed Load: UDL), or Single Axle (Dynamic Load) capacities; under heavy braking it is quite feasible to have the full weight of the fork truck acting through its front wheels only, therefore it is important to ensure the single axle rating of the mobile ramp is sufficiently high.

- Frequency of use

- Load dimensions – The chamber ramp should take into account the AUT being loaded or unloaded.

- Fork lift type – 3-wheeled fork trucks for example will put additional pressure on the flooring of a movable ramp; hence it is important to ensure we’ve have accounted for this in the ramp design.

- Height vs. range, (length) – The maximum recommended incline of a typical ramp is ~5 degrees or 1 in 12; therefore, it’s critical that we determine the available space outside the chamber door and don’t protrude into an aisle or a high traffic area where an injury could occur.