Woven wire is made up of individual strands of wire woven to create an open area product. This can create issues when trying to form shapes or maintain consistent openings when implemented into a product. Woven material has a tendency to fray or unravel making it difficult to hold shapes and tolerances, or the strands move, which results in inconsistent opening sizes or conductivity.

Slit and Stretch: How Expanded Metals Are Made

As one homogenous structure, expanded metals are more reliable materials for producing die cut shapes or patterns with tighter tolerance. Also, the openings are very consistent making it ideal for applications where pore size is critical or repeatable conductivity is essential for the performance of the product. Engineers also have to deal with the added thickness of a woven product where overlapping strands limit how thin a product can be produced. Expanded materials from foil or film grade materials allowing for thinner, and in return, lighter products with better performance.

As an alternative to perforated, the expansion process doesn’t produce scrap and better yield rates. With perforated products, the amount of material scrapped is based on the open area of the product. Fifty Percent (50%) open area will produce 50% scrap. This has to be taken into consideration into the price of the material. Because the expansion process is “slitting and stretching” the material, you are yielding more material than what is input. So for the same 50% open area, you are gaining 50% more product. This makes expanded material ideal for reducing cost in a product especially where higher performance materials are used.

As expanded metals have proven their performance and grown in popularity, manufacturing industries have pushed hard for even thinner and wider materials. 10 years ago, materials could be made as thin as 50 microns and as wide as 12 inches. Now, metals can be expanded down to 25 microns thin and widths up to 48 inches. Dexmet has even produced expanded materials 18 microns thin.

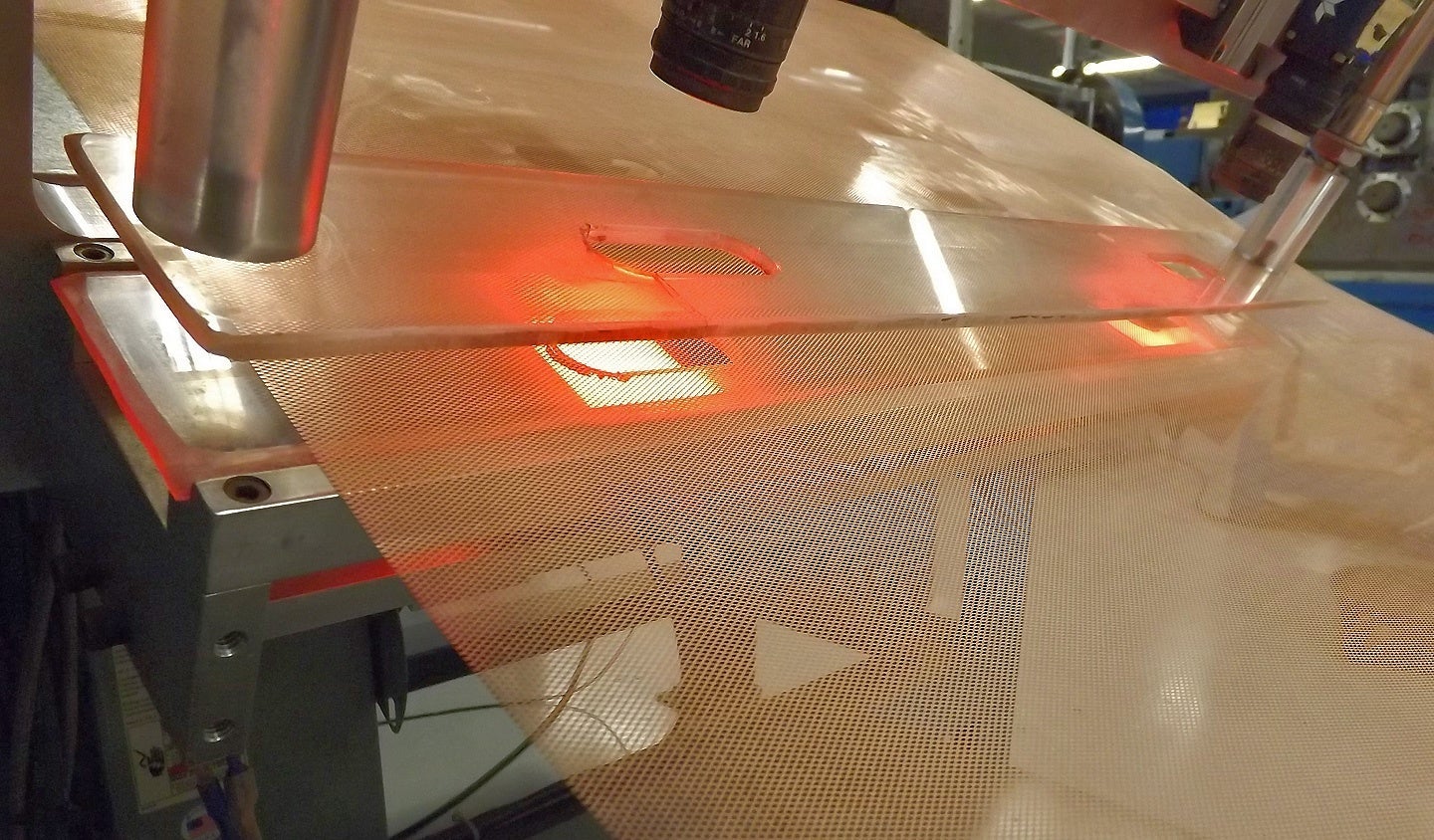

Through a slit and stretch process, raw ductile metals, or polymers, are “expanded” to create an open area product. And manufacturers can customize the material’s thickness and the number and size of openings to suit their specific applications.

How are Expanded Metals Made?

Everything from aluminum and stainless steel to zirconium and custom alloys can be expanded to meet your specific requirements. Before starting the expanding process, you must choose your parameters:

- Ratio of open area to metal/polymer

- Opening size

- Weight of material

- Conductivity (If critical)

- Overall Thickness

The exact dimensions of the open area are also key variables:

- Long way of the diamond (LWD) – Measured from the center of one node to the center of the adjacent node, the LWD is always parallel to the width of the coil and corresponds with the diamond dimension.

- Short way of the diamond (SWD) – Measured from the center of the node to the center of the node, the SWD is perpendicular to the width of the coil . For each fixed LWD dimension there is a SWD range.

- Strand width – The amount of metal slit from the parent metal in forming the mesh. The strand thickness is directly proportional to the machine’s feed rate.

With your requirements defined, our operators choose from 1,000 different precision die tools. After attaching the die that will optimize your diamond geometry, the machine is then programmed for a specific feed rate, tool geometry (profile) and tool travel (stroke). Finally, the rollers push your material into our custom-designed and built machine where the die slices and pushes away the material in a single motion to create the openings. After exiting the machine, the material is calendered between a set of rollers to qualify the overall thickness across the width of the material.

After expanding, secondary processes can be performed to achieve additional performance parameters if required. From slitting material to exact widths, to annealing or strain relieving, or even die cutting to require piece specifications. One process that is regularly performed for a more symmetrical opening is a proprietary pulling process. This is ideal for providing isotropic conductivity because without this process, the conductivity of your material will be three times greater lengthwise than it will be widthwise. In aircraft manufacturing, isometric conductivity allows manufacturers to build larger panels with consistent conductivity over a large surface area.

Performance coatings is another unique secondary process that can be performed. These coatings can range from adhesion promoters to conductivity enhancers. The adhesion promoters provide improved bonding when materials are utilized in laminants, specifically fiberglass or carbon fiber panels. The conductivity promoters are different formulations that reduce impedance on battery electrodes for better performing cells.

It’s important to note that there are over 100 expanded metal manufacturers. However, the majority of them can only produce metals as thin as 500 microns. Only a handful of manufacturers can create metals as thin as 25 to 125 microns.

Optimal Applications of Expanded Metals

Expanded metal solutions are widely used in the aerospace, electrochemical, medical and automotive industries that require highly-precise open-area metals to improve their end products.

As mentioned, aircraft manufacturers use expanded metals to lighten their planes. Some manufacturers are turning to carbon fiber materials to accomplish this goal, but carbon fiber is susceptible to lightning strike damage. They need conductive metal to protect against lightning strikes – a utility forecasted to be worth 5.52 Billion USD by 2022.

In the alternative energy space, increased power output requirements are forcing wind energy turbine manufacturers to build larger and larger blades. To increase the size of their blades while maintaining light weight, many of these manufacturers have also turned to carbon fiber. But they too have suffered lightning strike damage.

Expanded metals are also used in electromagnetic interference shielding to maintain normal operation of an electronic circuit or device. EMI gaskets made of expanded foils establish a frequency barrier to shield electronics along seams and openings in electronic enclosures.

Built for High-End Performance

Cutting edge applications require cutting edge materials. Expanded metal foils are increasingly adopted by manufacturers looking to make advancements with their products. The enhancements that engineers across many industries have achieved with expanded materials has opened the door to new possibilities with new applications. What cutting edge possibilities can you realize with high-performance materials?