The Next Frontier for Coil Coatings

With 30 years of leadership in ultraviolet- and electron beam-curable coatings for wood, PPG is bringing the energy efficiency and high speed of energy curing to metal coil coaters with the DuraNEXT™ family of primers, backers, topcoats and clearcoats.

What is energy curable technology?

Unlike traditional coil coating systems that require very high temperatures to drive the curing process, DuraNEXT coatings use an electron beam or ultra-violet energy to convert a liquid coating into a fully cured solid finish in seconds, without any significant loss of thickness or weight. They are also formulated without solvents so they produce little to no volatile organic compound (VOC) emissions.

PPG Breakthrough Brings Energy Curing to Metal

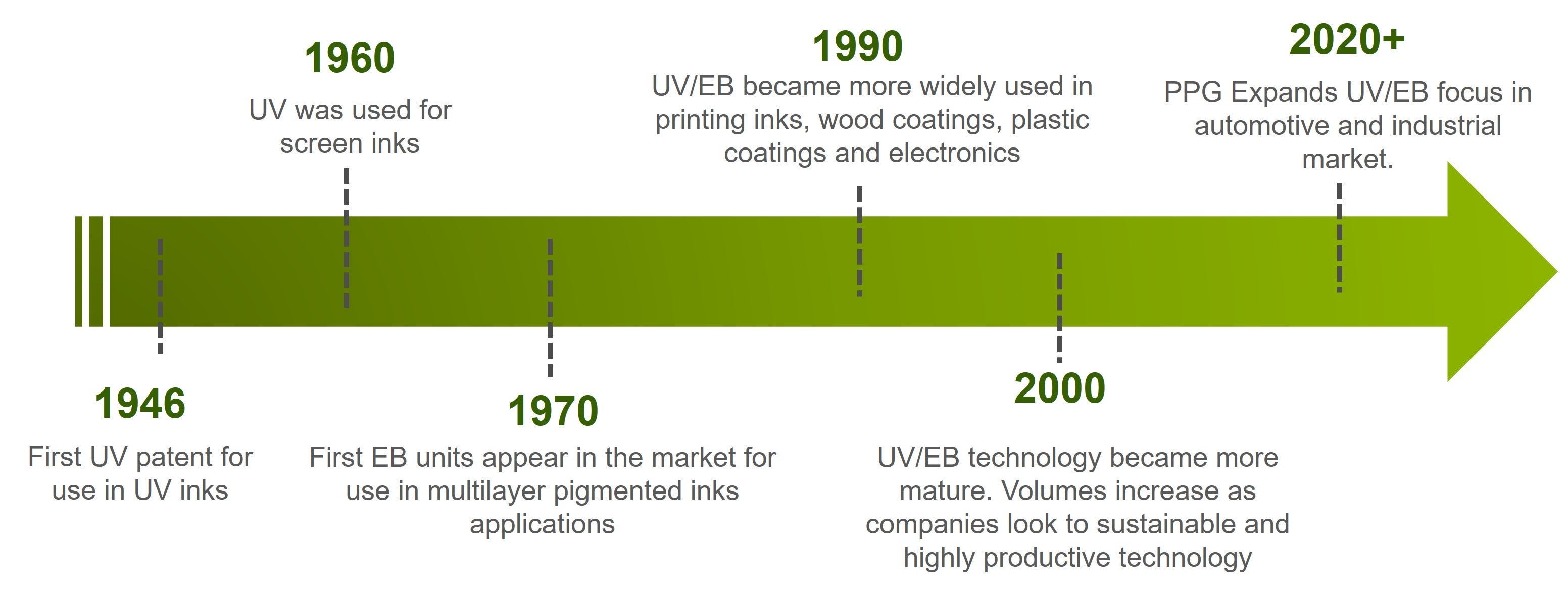

Energy-curable coatings were first introduced over 50 years ago with adoption of ultra-violet (UV) curable coatings for wood. The development of electron beam (EB) curable coatings soon followed. PPG was an early pioneer of these advanced finishing solutions and still remains at the forefront of the industry. Today, UV- and EB-cured protective finishes have continued to evolve and are widely used on substrates like vinyl, composites, wood and now – coiled aluminum and steel.

Introducing PPG DuraNEXT EB Clearcoat for Digital Printing on Metal

Why choose DuraNEXT

- Highly flexible, resistant to abrasions, impact and chemicals

- Excellent weatherability with UV- and humidity-resistant

- Resists color and gloss facing

- Requires minimal maintenance and easy to clean

- Allows for infinite design possibilities on digital printing on coiled steel

Typical uses

- Garage doors

- Cladding

- Commercial buildings

- Barns

- Sheds

UV/EB-curable coatings benefits

- Energy savings/improved productivity: Reduced energy use vs. thermal curing technologies

- Sustainability: Generally made without solvents, low or even zero emissions

- Coating properties: Enhanced durability with excellent hardness and abrasion/chemical resistance

- Operations: Compatible with many application techniques

- Handling: Parts can be handled almost immediately for packing, storage and shipping

Basecoats

Available in a full range of glosses and colors for both interior and exterior applications and with options that include smooth, textured and wrinkled finishes. These can also be formulated as a one-coat direct-to-metal solution.

Clearcoats

Engineered to preserve digitally printed inks with a protective layer that adds weatherability and scratch- and abrasion-resistance for residential and commercial applications.

Primers

Available in UV-curable formulations. UV primer can be used under an EB topcoat or with a conventional thermal cure topcoat. These primers could also be used in conjunction with a wet-on-wet applied topcoat and cured with EB in a single pass.

Backers

Available in both UV and EB formulations to accommodate various application equipment setups. These can be applied over a primer or used as a direct-to-metal application.

WHAT IS THE POWER OF A PARTNER?

PPG goes far beyond paint to provide a true partnership in your success.