Unlike fabricated metal parts that are painted after they are formed into their designated shapes, many metal parts are pre-painted before fabricating via the coil coating process.

PVDF Versus SMP Coil Coating Systems

As the name implies, this method starts with coils of steel or aluminum that are coated and cured in a continuous process. They are then cleaned, chemically pretreated and roll-coated before curing, cooling and recoiling for shipping to a manufacturer or fabricator for cutting and shaping into its end use form.

This roll-forming process is commonly used for building applications like trim, garage doors, curtain walls, roofing and gutters.

Coil coating is a big part of the paint and coatings business with millions of tons processed annually each year in North America alone and demand is rising, particularly due to growth in the construction sector.

While coil coating is a standard process, the type of resin chemistry used in the paint process varies, based on a variety of factors including budget, end-use and level of protection needed against corrosion, weathering and wear.

Coil Coating Systems - PVDF Resins versus SMP

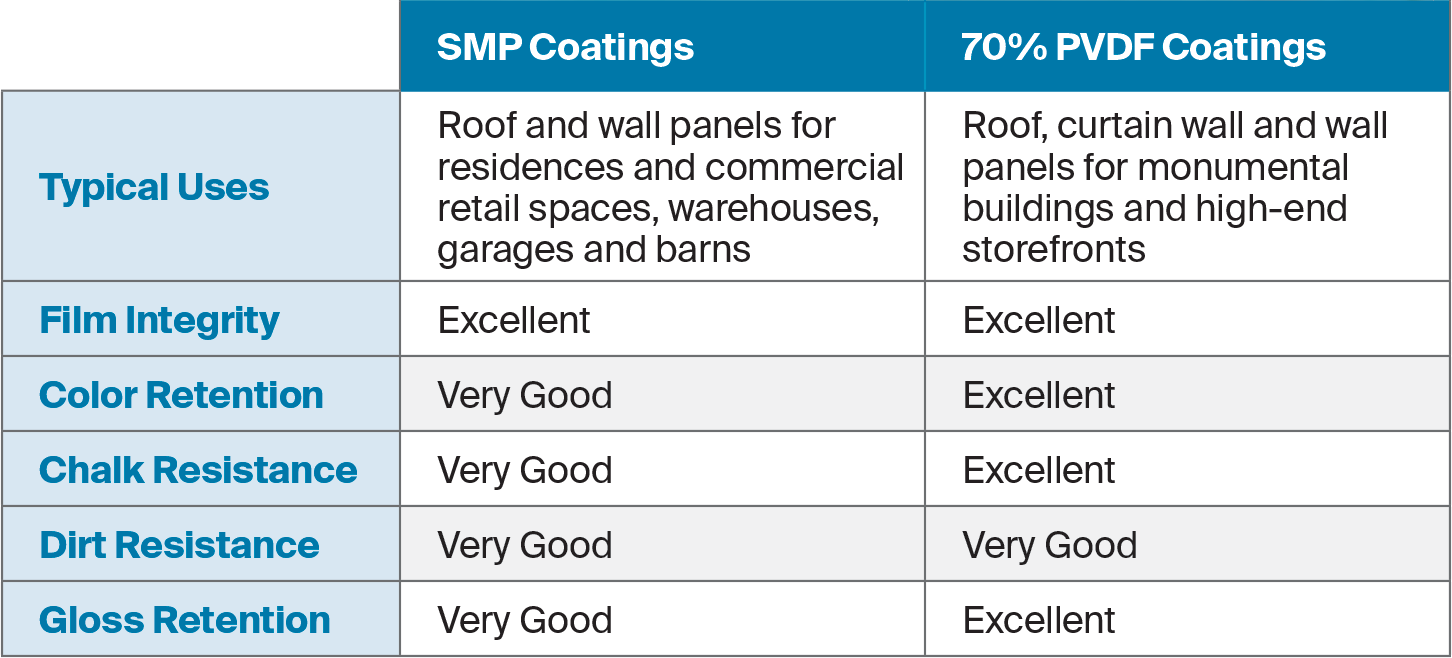

Silicone Modified Polyester (SMP) and Polyvinylidene Fluoride (PVDF) coatings are two commonly used resins in coil applied systems for the metal building products industry.

Because these polymers are engineered to withstand extreme weather conditions, each provides a formidable barrier against UV exposure, humidity, salt spray and chemicals that can degrade the coating system.

While both are excellent choices for preserving the structural integrity and aesthetics of metal building components, there are important distinctions between them due to the specific resins, pigments, solvents and additives used in their chemical compositions.

PVDFs have a long, well-documented history as one of the most widely used coating systems for the premium building products exterior market, heralded for unsurpassed performance, film integrity and long-lasting resistance to chalking, fading and extreme weather conditions.

- Well-suited for extreme environments

- Best with intense sun exposure

- Proven performance across wide color space

- Can be used with cool coating technologies

- Color stability for decades

- Optimal warranty for chalking and fading

- Good film adhesion

PVDF coatings are typically used on monumental buildings.

SMP coating systems are an excellent choice for a wide market of building end uses with robust film properties that are engineered to last and meet the demands of roll formers and installers.

Due to their competitive pricing and durable finish, they are popular options for residential, industrial and agricultural uses.

- Superior film adhesion

- Available with cool coating technologies

- Attractive price to performance ratio

SMP coatings are typically used on warehouses.

While 70% PVDF formulations like PPG DURANAR® liquid coil coating remain the gold standard for metal protection and aesthetics, SMP systems like PPG DURASTAR ® ULTRA-COOL® coil coatings that are engineered with newer, premium resins and pigments are making it a viable option for a growing array of building applications.

PPG recently published a white paper that explored the differences between 70% PVDF and SMP coatings in terms of their chemistry, expected long-term performance, cost considerations, UV durability and color stability.