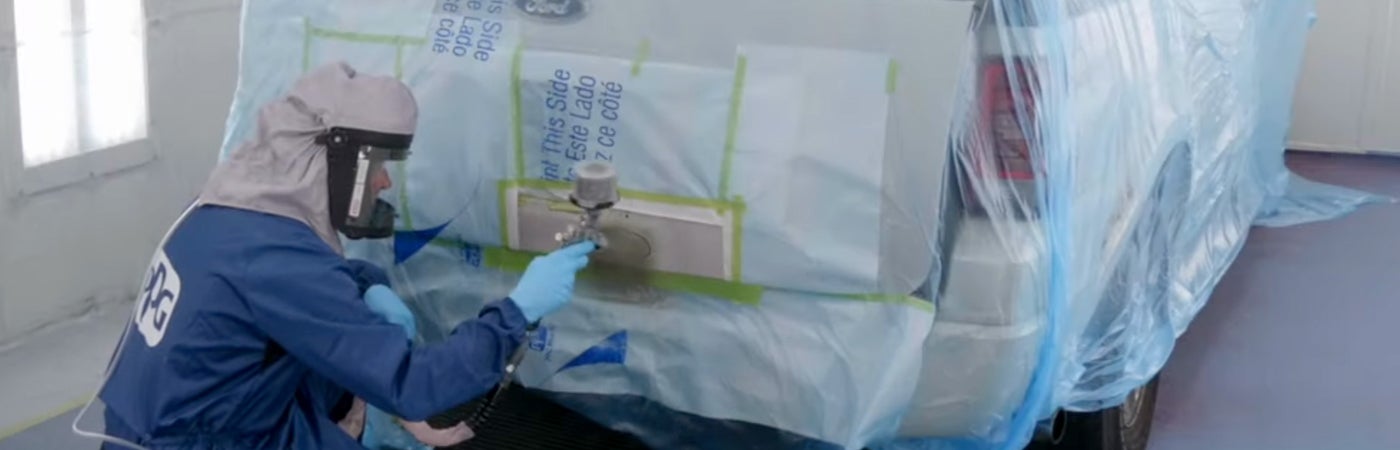

When preparing aluminum substrates, it is important to follow proper surface preparation and priming recommendations to ensure good adhesion and corrosion protection. This standard operating procedure (SOP) covers the process for successfully preparing a bare aluminum surface. Before beginning any repair, it is important to always wear the recommended safety protection required for the job.

PD-0115A: Metal Surface Prep - Bare Aluminum

Step-by-Step Instructions

- A technician should review a work order to ensure that all parts to be painted are present and repairs are understood.

- Clean the entire part and use a local VOC regulation surface cleaner and a clean towel. Dry thoroughly.

- Inspect the part for imperfections and damage. If repairs are necessary, refer to all process documents for detailed instructions.

- After making any necessary repairs, sand exposed aluminum using a DA sander with P120 -P180 grade paper and interface pad. Re-clean the entire part. To avoid galvanic corrosion, never use the same piece of sandpaper on both steel and aluminum. Avoid cross-contamination of airborne steel and aluminum particles generated in the same shop areas. CAUTION: under proper conditions, aluminum dust can be combustible

- Prime or chemically treat bare aluminum substrates immediately. Oxidation can form on exposed aluminum surfaces as quickly as 15 minutes. If necessary, scuff or re-sand before the primer process.

Method 1: Etch Primer - refer to Product Data Sheet for detailed instructions.

Method 2: SX Metal Treatments - refer to OC-36 Product Data Sheet for detailed instructions.

Method 3: Epoxy Primer - refer to Product Data Sheet for detailed instructions.

To prevent dissimilar metals corrosion where bare metals make contact with one another (bolts, rivets, hinges, etc.) ECK® (Electrolysis, Corrosion, Kontrol) should be applied. Refer to ECKPB01 for complete details.

*Cannot be used in some areas due to VOC heavy metal restrictions. Refer to local regulations.