Compact Paint Systems

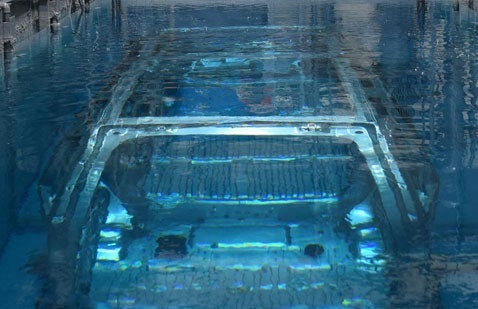

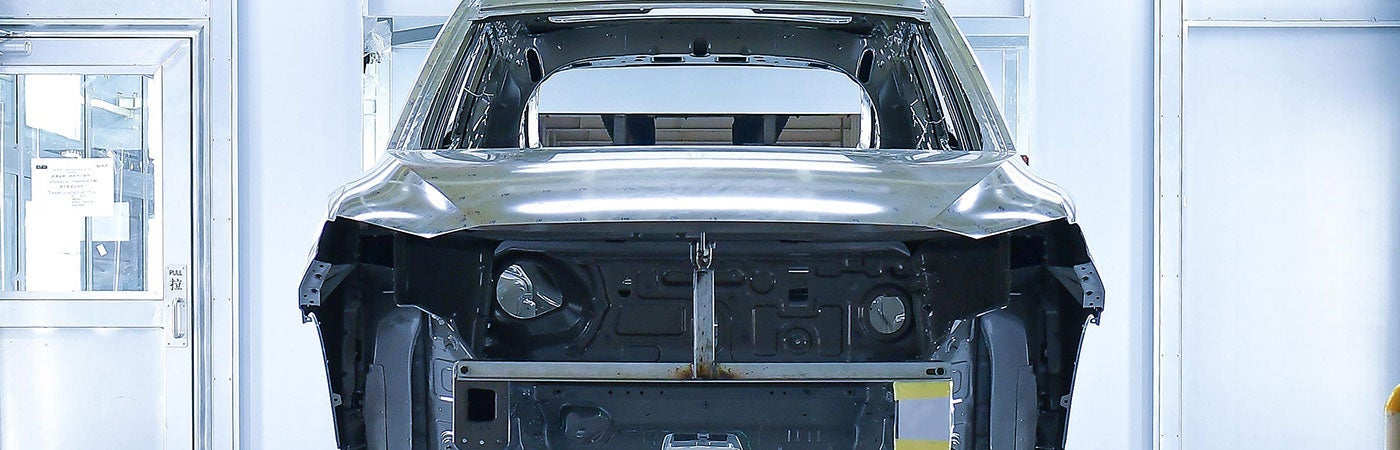

No matter which topcoat technology currently being in automotive manufacturing facilities – B1:B2™ and 3C1B, in water or solvent versions – PPG has a Compact Paint System to match. Our commitment to sustainability led us to the current solutions in compact processes and will continue to encourage innovation.

Our Compact Paint Systems allow customers to reduce VOC emissions, reduce energy consumption and associated CO2 emissions, lower initial capital and operating costs by eliminating the need for a standalone primer and associated processing. They also reduce the paint shops overall footprint and increases the facilities throughput.