Electrocoat

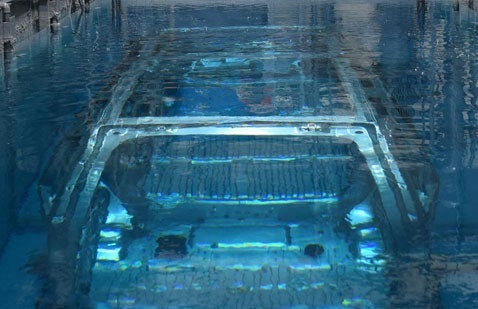

PPG has been a global leader in electrocoat technology to the automotive industry for more than 60 years, protecting over 750 million vehicles in this time. PPG introduced the first cationic electrocoat for automotive use and continues to bring innovative, cost-saving solutions to the automotive industry.

Our full line of cathodic dip primers are used by all major automobile manufacturers worldwide. PPG’s award-winning lead-free, low-VOC and high throwpower technologies are recognized as best-in-class materials providing exceptional corrosion resistance, efficient operation and optimal topcoat appearance.